The principle variables of sheet forming including the interactions between variables are clearly explained as a basic foundation for the most effective use of computer aided modeling in process and die design.

Sheet metal forming processes and applications.

Sheet forming fundamentals are thoroughly addressed in this comprehensive reference for the practical and efficient use of sheet forming technologies.

To deformed the raw material.

The sheet metal is placed over a die block at which point a punch presses down.

Thicknesses can vary significantly.

Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters.

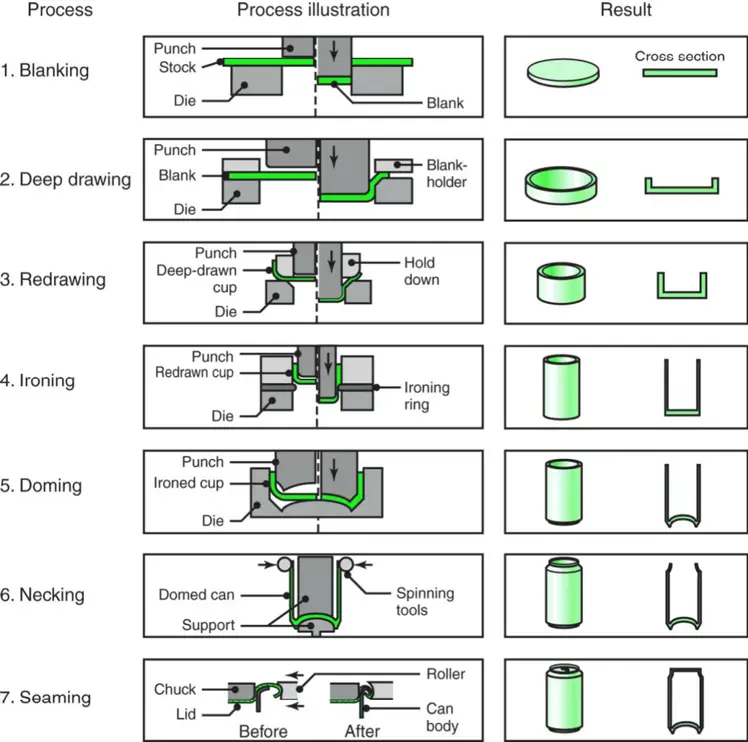

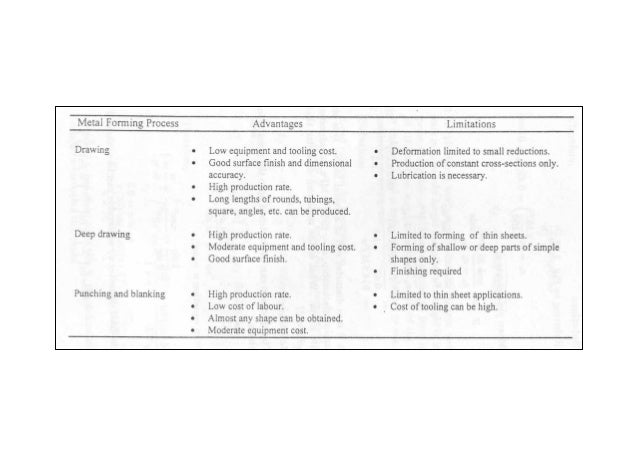

Classification of basic sheet forming processes bending deep drawing shearing.

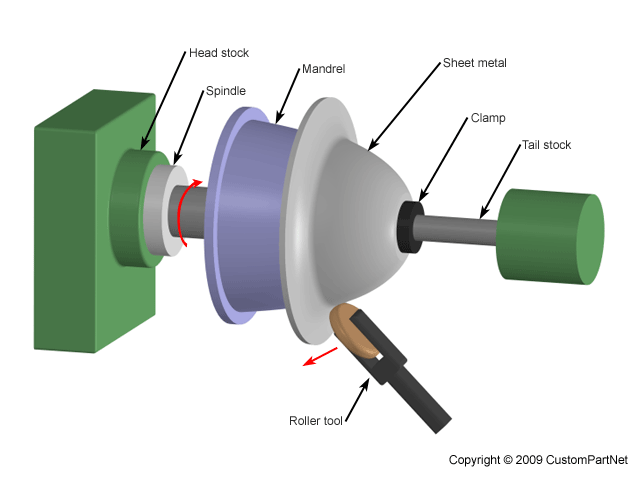

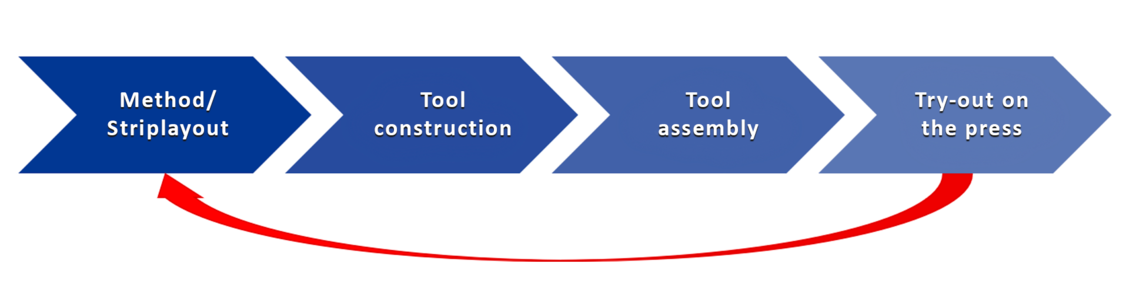

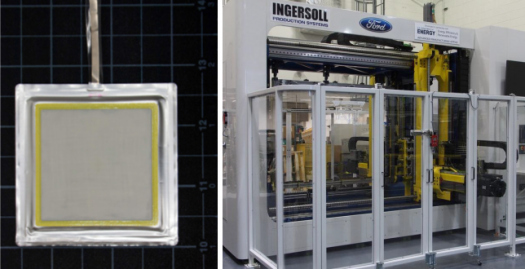

Tools include punch die that are used to deform the sheets.

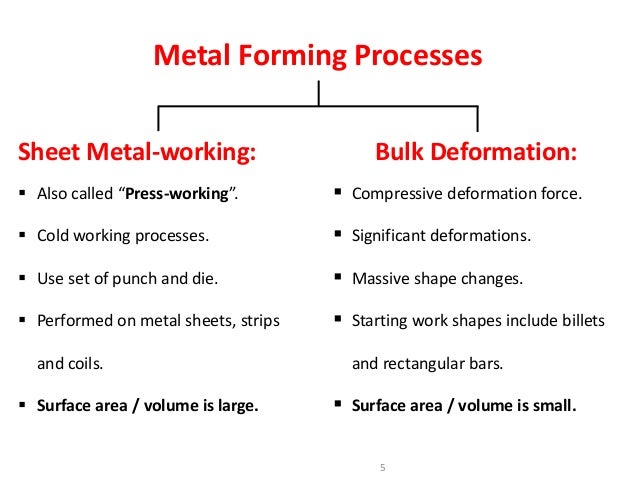

Forming process also known as metal forming is a large set of the manufacturing process by which a raw material converted into a product.

This practical and comprehensive reference gives the latest developments on the design of sheet forming operations equipment tooling and process modeling.

Individual chapters cover all major sheet forming processes such as blanking bending deep drawing and more.

Ii find read and cite all the research you need on researchgate.

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal.

9 3 temperature and sheet metal forming.

Individual chapters cover all major sheet forming processes such as blanking bending deep drawing and more.

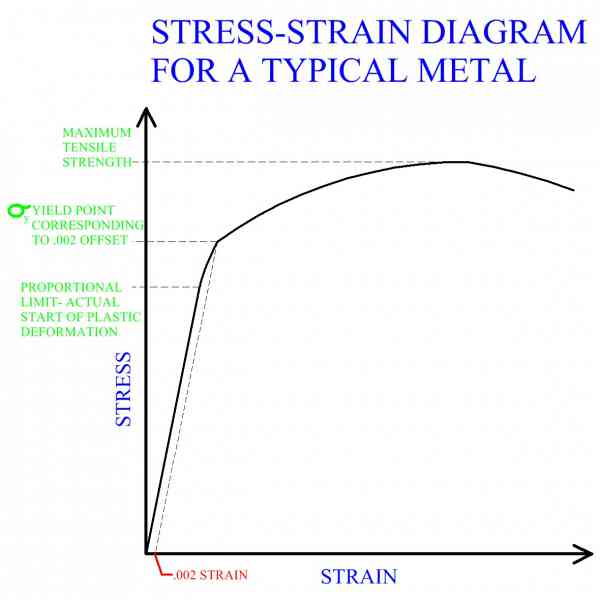

Most manufacturing processes involving sheet metal are performed at room.

Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters.

Processes and applications vol.

Another common sheet metal forming process is bending.

Sheet metal forming processes and applications details.

Other chapters cover sensors and die materials which are critical for practical sheet forming applications.

In this process we apply stresses like tension compression shear etc.

Sheet metal applications as beverage cans packaging kitchen utensils and applications where corrosion resistance is a concern.

The surface area to volume ratio of the starting metal is relatively high.

Companies typically perform bending on sheet metal using either a brake press or similar machine press.

Request pdf on aug 31 2012 taylan altan and others published sheet metal forming.

Curling is a forming process that involves de burring sheet metal to produce smooth edges.

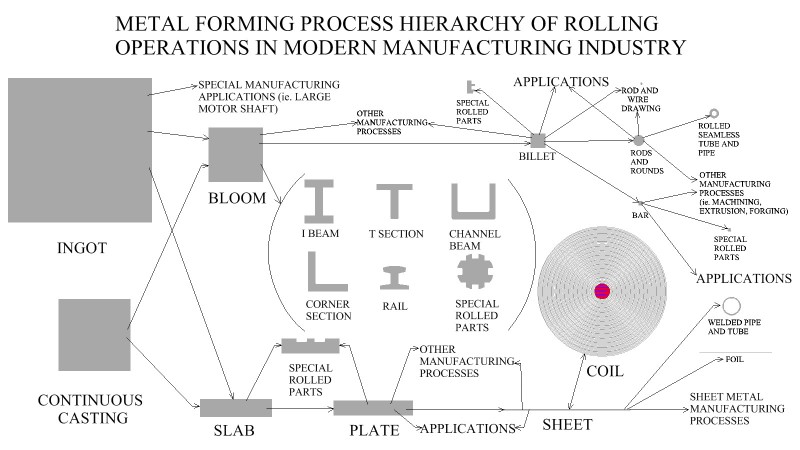

The example of forming processes are sheet metal manufacturing forging rolling extrusion wire drawing thread rolling rotary swinging and so on.

Sheet metal forming involves forming and cutting operations performed on metal sheets strips and coils.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered.

Individual chapters cover all major sheet forming processes such as blanking bending deep drawing and more.